CDA's

Microfunctional Solutions

Microstructures from plastics

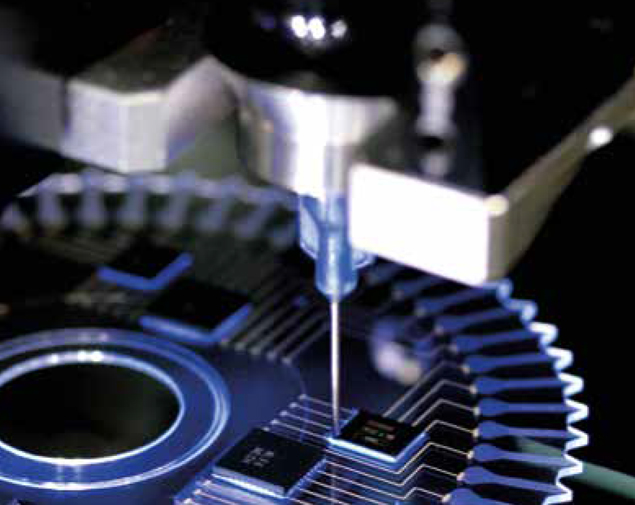

CDA is a leading manufacturer of complex microstructures from plastic material. In the last few years CDA has modified the traditional duplication techniques so far that a proprietary technique has grown out of it for the successful serial production of micro-optical components. CDA’s success in the various fields of microstructural applications developing rapidly has been achieved by pooling of core competences in the area of volume production of precision microstructures from polymer, the comprehensive engineering know-how and flexibility in production.

CDA µFUNCTIONAL PRODUCTS

MICRO-OPTIC

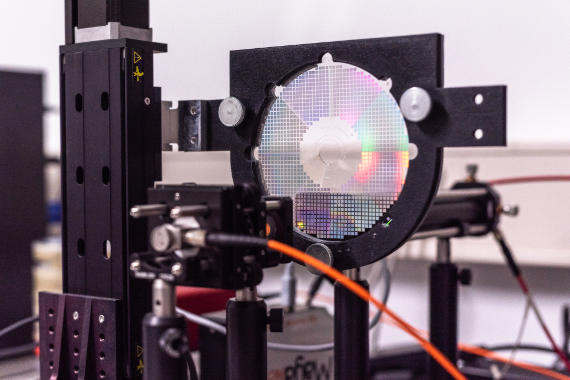

Optical encoders are components that contain alternatively and periodically unstructured subareas followed by scattering subareas and thus allow a relative encoding of the position.

Diffusors are specifically designed for the relevant applications and scatters the light in the form needed.

Fresnel lenses - The design of the Fresnel lens ensures a large aperture and short focal length without the mass and volume of materials required for a conventional lens design.

Diffractive optical elements DOE – Light of punctiform sources can be diffracted at regular gratings and microstructures in such a way that almost any pattern can be created.

MATERIAL

CDA has developed methods to replace materials such as fused silica or glass by modified plastics.

If other than the polymers listed below are needed for your products, contact our customer service team who will inform you on the relevant availability.

Polycarbonate, COC (TOPAS), COP(ZEONEX), PMMA

OUR SERVICES

It is CDA’s objective to organize the prototyping as smoothly as possible. Our team provides assistance in finding the optimal design for your application.

Our capabilities for a swift development of prototypes are focussed on significant cost cutting and minimal lead times. The proprietary technique makes it possible to embed 4" and 6"masters in the production chain and thus use the existing silicon masters.

To ensure the quality of your samples, we do the prototyping on the same machines as the serial production.

Sometimes it is useful to reduce transport times and costs. To this end CDA offers basic assembly as part of the back-end processes.

Let us know if you are interested. To make sure that your product arrives safely at the place of destination, we provide a range of packaging options for any need.

We have got plenty of space.

For example, for 9,000 pallets of your products. We take charge of storage and dispatch of goods. Our high-bay warehouse has a capacity of 9,000 storage locations. Our warehouse management system is fully computerized so that we can meet your logistic and sales needs in a flexible manner.

Flexible and customized shipping.

In Germany the goods are usually dispatched within 24 hours. If need be, we can also deliver goods to OEMs worldwide. We are prepared to meet your needs whether these are special requests in terms of shipping or transport of individual products. At our logistics centre your products are made ready for dispatch in a fast and reliable manner.